Insulated Concrete Forms

Insulated Concrete Forms or ICF are stackable foam blocks that can be filled with concrete to form a strong and incredibly well insulated wall assembly.

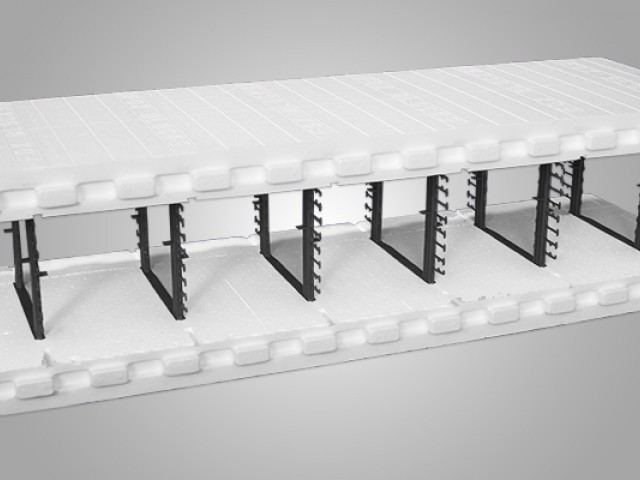

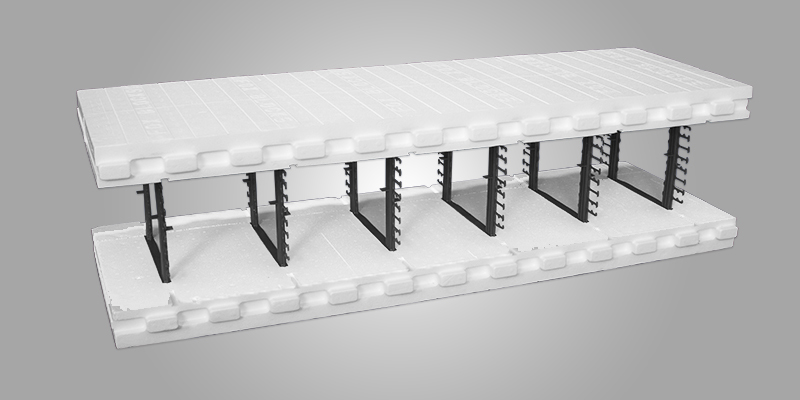

The Straight Block typically makes up between 80-85% of the ICF wall assembly on most residential and commercial jobs. This block has six strong, full-length injection, molded plastic ties made from Polypropylene (PP) regrind resin that are well marked with the words “Fox Blocks” located on both sides of the block. These ties secure the two pieces of modified Expanded Polystyrene (EPS) foam together that make up each block type. The blocks are stacked tightly together and inter-locked end to end to the desired wall length. Once a single layer or course of ICF blocks is installed, horizontal reinforcing steel bars are inter-locked securely together in the ties of the blocks, then another course of Straight Blocks are placed firmly on top as the wall is built. To improve construction wall strength during installation, each course of blocks should have their end-joint connections staggered in a running bond method from the course adjacent to it. This installation method is typical for all Fox Blocks ICF form types and sizes. Fox Blocks has proven results for setting exceptional standards in cost control, planning, scheduling and project safety. We have experience that gives us a competitive advantage over others in our field.

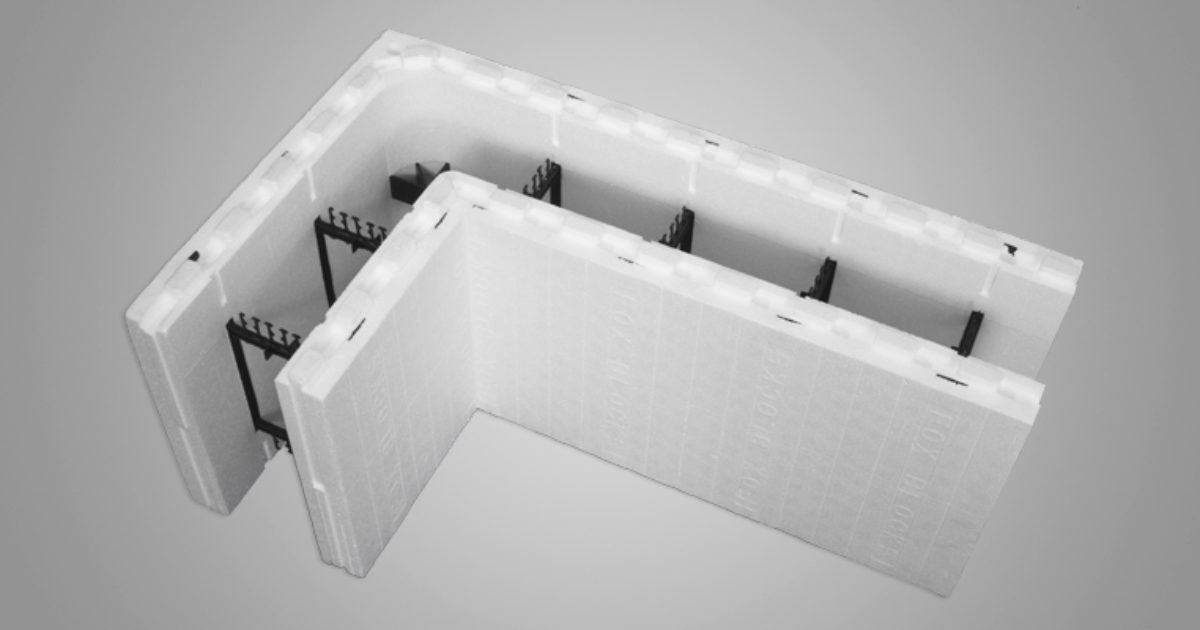

The 90 Degree Corner Block typically makes up 15-20% of the ICF wall assembly on most residential and commercial jobs. This block has six strong, full-length, injection molded plastic ties made from Polypropylene (PP) regrind resin that are well marked with the words “Fox Blocks” located on both sides of the block. The corner block also has one patent pending corner bracket designed like no other in the ICF Industry. This 7/32″ thick x 1-1/2″ wide corner bracket was engineered to add more strength/support to the block because it connects the inner/outer modified Expanded Polystyrene (EPS) foam panels together and is designed to eliminate blow-outs during the concrete pour.

Features and Benefits

Unlimited Design Detailing and Finishes

With blocks available in a number of shapes, sizes, and concrete core thicknesses, we can create any design you can dream up. Plus, our wall assembly works with all exterior/interior finishes you choose to use, be it EIFS, traditional stucco, brick, stone, fiber cement siding or drywall.

Unparalleled Comfort and Quiet

Our wall assembly provides indoor comfort and improves a building’s performance characteristics for the interior environment by eliminating moisture intrusion, managing the airflow and allowing for accurate climate control and minimizing sound mitigation.

Strength Against the Elements

Our ICF wall assembly meets and exceeds safety/resilience/durability requirements for Division 03 Concrete, Section 031119 ICF; Whole Building Design Guide (WBDG) Unified Facilities Criteria (UFC) & FEMA-ATFP Federal Military and DoD Standards FEMA-ATFP.

Lifetime of Savings

The performance characteristics of our wall assembly can reduce a building’s heating and cooling cost dramatically (up to 50%) and puts Net Zero Energy goals within reach.

Dimensions

6" 11.25" 48" 0" 5.33 sq. ft. 0.099 cu. yd.

8" 13.25" 48" 0" 5.33 sq. ft. 0.132 cu. yd.

10" 15.25" 48" 0" 5.33 sq. ft. 0.165 cu. yd.

12" 17.25" 48" 0" 5.33 sq. ft. 0.198 cu. yd.